EMC DESIGN SOLUTION

TYPICAL EQUIPMENT WHERE EMC NOISE IS GENERATED

- Variable Speed Drives Fans/Heaters

- Motors

- Transmitting Equipment (Wireless Data Transfer)

- Fluorescent Lamps

METHODS OF ATTENUATING NOISE

In order to reduce noise from an electrical system, the CMP TSZ/TSZe has a specially designed EMC spring that provides 360 degree low impedance contact with the cable shield. Using CMP’s EMC locknut to provide the best contact for continuity between cable gland and the wall of the shielded metallic enclosure, combining to form an ideal Faraday Cage.

The Faraday cage acts as a barrier to electromagnetic interference redirecting electrical noise away from sensitive circuits within the enclosure.

Cable and enclosure manufacturers offer various shielded solutions, designed to attenuate or provide a barrier to electrical noise. However, without effective grounding of the cable shield at the cable entry point, the effects of these solutions may be negated!

CMP TSZ and TSZe EMC cable glands offer a simple and proven effective termination method to ground the cable shield to the enclosure.

EMC CONNECTIVITY

TruSeal EMC cable glands provide optimum noise attenuation performance in terms of protecting the connected equipment, and limiting radiated EMC emissions.

CMP TSZ and TSZe EMC cable glands have a specially designed EMC spring shaped to reduce penetration of EMI and maximise 360 degree contact for a wide selection of cable diameters and shield types. The spring material is specifically formulated to provide superior electrical properties, with low impedance continuity with the cable shield.

This EMC spring design provides a simple and proven effective termination method to ground the cable shield to the enclosure and simplify inspection.

EMC TESTING

EMC testing is essential for compliance with international directives, regulations and standards (such as IEC or FCC). These standards help to ensure all electrical equipment is safe, reliable and operate alongside other equipment without interference.

Electrical equipment is typically tested to ensure the emissions (unwanted EMI or electromagnetic interference) is reduced below industry standard acceptable limits, to prevent disruption of neighbouring equipment. Equipment is also tested for its susceptibility and immunity to EMI; the aim is to ensure a sufficiently high level of immunity, which will prevent the equipment from being affected by unwanted noise.

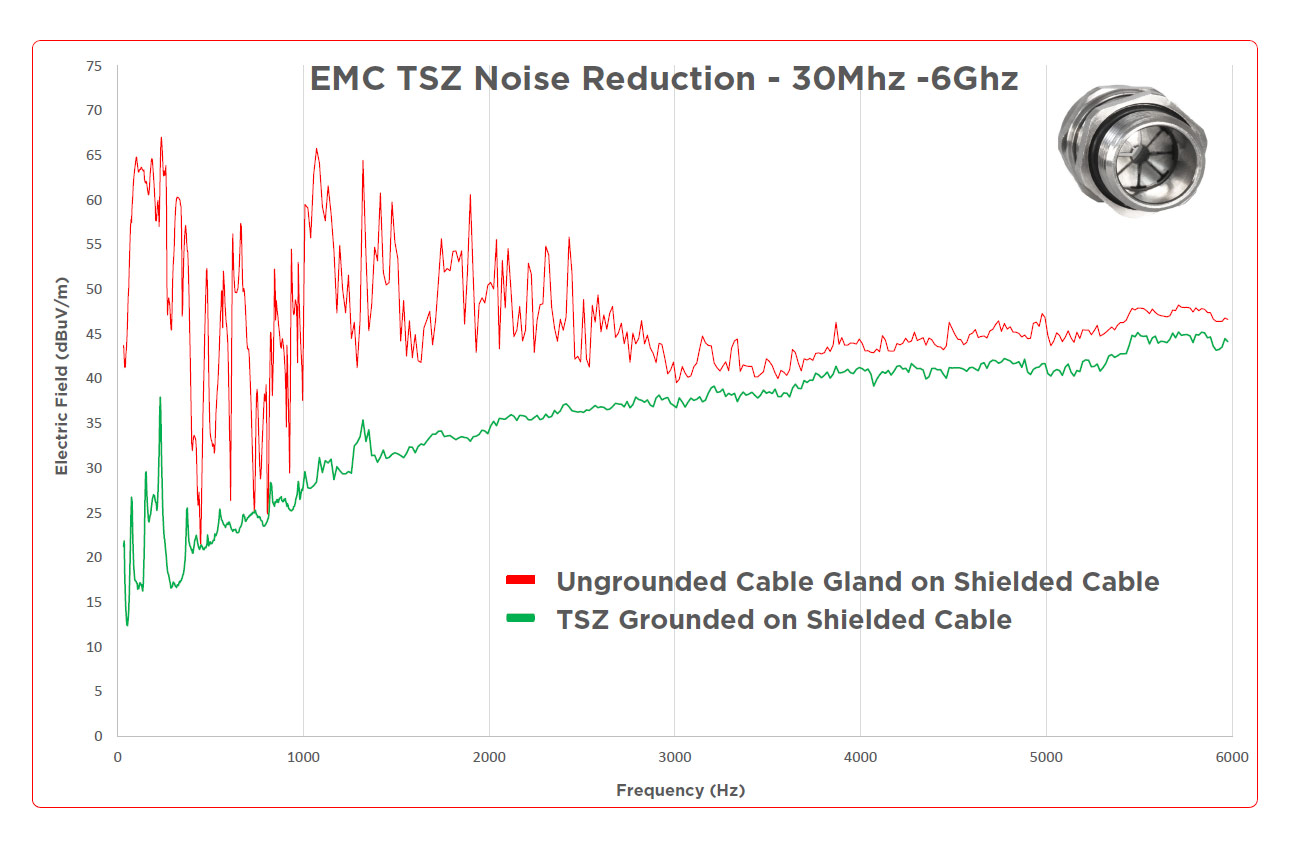

CMP TSZ and TSZe EMC cable glands can assist to improve immunity and reduce emissions and they have been tested to validate this performance. Below is a graph showing the results of EMC compatibility testing. A typical EMI across the frequency range is shown in red and once adding the TSZ/TSZe cable gland, the result in green shows how noise is attenuated across the range.

EMC TSZ Noise Reduction - 30Mhz -6Ghz

- Ungrounded Cable Gland on Shielded Cable

- TSZ Grounded on Shielded Cable

For reference, domestic supply is 50-60 Hz and bluetooth is 2.4 GHz. Mobile data transfer is up to 5 GHz.

By identifying and mitigating potential issues during the design and development stages, selection of proven termination solutions can assist the electrical products to meet EMC requirements. CMP cable glands enhance EMC performance, reducing the risk of malfunctions, and ensuring seamless operation alongside other electronic devices.

Back to TruSeal Overview